The biggest hurdle for the Industrial Internet of Things (IIoT) is standardised data communication. Only when open data standards are embraced by the automation manufacturing community, can the true value and operational benefits of IIoT be realised.

Open wireless networks

One challenge which IIoT faces is the need to connect devices, often legacy ones which are not Ethernet enabled, or those which are outside the reach of cabled Ethernet networks. While IEEE 802.11 WiFi networks are one solution their range and other technical restrictions can be a barrier.

advertisement

LoRaWAN and Sigfox

Low power, wider area open networks (LoRaWAN) can meet the increasing requirements of mass IoT applications Their combination of low device integration cost, low connectivity fees, low power, high network capacity, and long range have made them attractive to industrial applications which often require a small amount of data to be transmitted frequently.

4G and beyond

There is much excitement about the arrival of 5G, but the reality for industrial applications is that 3/4G offers more than enough in terms of data rates and latency for the vast majority of industrial IoT tasks.

Cellular network coverage is continually improving and the choice of industrial cellular hardware, such as modems and routers, is continually expanding. This combined with the relatively low subscription and hardware costs makes cellular connectivity an attractive option for many IIoT projects.

Open data standards

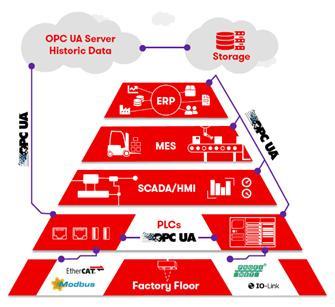

Industrial IoT enables a broader range of technologies which have previously not been connected to IP-based networks and connects them via new, emerging networks. However, they still need a common way to communicate if the information is to be usable. Therefore, a strong case exists for standardised ‘middleware’ which can be the key enabled to this fourth industrial revolution. OPC Unified Architecture (OPC UA) is a standard could make this a reality.

OPC UA addresses the need for standardised data connectivity and interoperability either in machine-to-machine (M2M) data connectivity within factory floor systems or device-to-cloud or server data transfer, such as production data passing from PLCs to an ERP system. In both cases OPC UA provides a secure, reliable foundation robust enough to facilitate standards-based data connectivity and interoperability.

The true value of IIoT can only be fully realised if communication between devices is based on a global communication standard that can satisfy a wide range of complex requirements. This could be a high speed one-to-many broadcast communication, or a secure client/server model for bi-directional communication and control. OPC UA supports both requirements.

Beyond simple ‘data’ sharing, a core IIoT era standard must facilitate rich information exchange, especially important when large amounts of data are pooled (aggregated) from a diverse eco system of third party systems found in typical production environments. The OPC UA standard’s object-oriented information modelling mechanisms directly fulfil this requirement while standardising the semantic data description, enabling the possibility of integration across all network layers as well as platform and vendor independence.

If IIoT is to become ‘business as usual’ the need to find a platform-independent data exchange standard is paramount. In many ways it’s the missing piece of the puzzle as there are numerous technologies which can help convey device level data onto a network, IO-Link being one example. However, allowing this data to be shared seamlessly and securely is vital in allowing industry to really harness the power of Industrial IoT and seize the benefits.